Advanced Industrial Handling Solutions

THERMAL SPRAY COATING

H.V.O.F (High Velocity Oxygen Fuel) Thermal Spray Coating

Continuous combustion of oxygen and fuel gases is produced by the Jet-Kote spray gun. It accelerate and project powdered coating materials into substrate at high velocity to form quality coatings. With particle velocity at Mach 3-5 and combustion flame temperature at 3,100 °C, this system produces extremely hard, dense and tightly bonded coatings suitable for applications of parts used in high pressurized environment (up to 20,000 psi), such as oil and gas industry. Excellent smooth finishing is achievable due to its low porosity level.

Characteristics:

•No distortion caused by spray process

• Possible to spray extremely hard coating

• Coating hardness up to HV 1,250 (± 74 HRC)

• Bonding strength: ± 1,900 kg/cm2

• Coating thickness: ± 0.05~0.25 mm

• Porosity: Less than 0.5%

Application

Step Cones

Wire Guide Rolls

Piston Rods

Plunger Bushes

Sheaves

capstan RIng

Mechanical Seals

Impeller Rings

Powder Spraying Process

Self- Fluxing alloy powder of nikel base, cobalt base, includes tungsten carbide can be sprayed by this process. Further treatment by fusing produces extremely dense and metallurgical bonded coating. This coating produces excellent wear and corrosion resistant to the surface. The Coating hardness produced can archieve HV 300 ~ 1,000 (30 ~ 75 HRC)

Characteristics :

No distortion caused by spray process

Possible to spray thick coating

Coating Hardness HV 400 (+- 40 HRC)

Bonding strength +- 200 ~ 400 kg/cm2

Ferrous and non- Ferrous material

Porosity 8~20%

Ceramic Rod (ROKIDE) Spraying Process

This Process uses special rods produced by Norton CO., USA. materials with various high concentration of Cr203,ZrO2, AI203, and Zro2-SiO2 are available to produce high quality, dense coating to achieve excellent war and corrosion resistance, anti-static and to be utilized as thermal barrier

Characteristics :

No distortion caused by spray process

Coating thickness : 0.25 ~ 1.00 mm

Bonding strength : 100 ~ 150kg/cm2

Porosity level : 0.3 ~ 0.5%

Only rod formed ceramics can be sprayed by this process

Ceramic Coating

Application for shaft&Seal side Area HRC

Wire Metalizing Process

This is the festtest and most common process to deposit metal and metal alloy coating using wire at law temperature

Application

Turbine Blades

Refining Rolls

Galvanizes Rolls

Can Rolls

Pump Plungers

Valve Gates

Piston Rods

Ball Valves

Paper Rolls

ABOUT COMPANNY

BUSINESS SCOPE

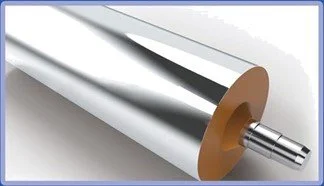

Hard chrome plating (usually used by paper, plastic, packaging, and other manufactories)

Full matte finishing (include semi mate, double matte, full matte, mirror and semi mirror)

Super mirror (usually used by plastic, film, rubber, carpet, packaging, paper and other indutries)

Thermal spray coating (include wire metalizing process, powder spraying process, ceramiv rod (Rokide) spraying process)

Various accesories include new fabrication extruder screw plastic, rubber injection moulding and repair screw unit

Machine & Sparepart processing service and trading (ultrasonic anilox roller cleeaning machine & Processing of Various mechanical parts)

Laser (Include emboss, anilox, coating,ceramic coating)

Bio Cleaning (channel cleaning by :”HCC Device”)

.

A beautiful world is a time of mutual prosperity, cooperation and harmony with nature. We are comitted to promoting the progress of the times, creating social welfare, and creating a better future with everyone. We believe that the restoration and remanufacturing of engineering services backed by our long-term accumulated experience and high technology will provide the best cooperation for our customers. Therefore our company's goal is to help make the world a richer, fairer and better place through our reliable services, and we'll keep and stand firm in our belief.

Contact Us

Interested in us? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!